The choice of 3D printing materials determines the quality of the work. How to choose materials like an expert? This article will reveal tips for 3D printing material selection.

Once we have an understanding of the material properties, we will explore how to select the most appropriate 3D printing material based on the function, appearance, and environmental needs of the project.

How can I ensure the consistency of plastic 3D printing material quality in batches?

The quality of 3D printing materials has a significant impact on the final product’s performance, appearance, range of applications, and production efficiency and cost. It is necessary to comprehensively consider the application requirements, material performance and cost to ensure the quality and performance of the product.

- Material selection: Strict certification of the materials used. Detailed numbering management is carried out for each batch of materials.

- Material Storage: Control the environment in which materials are stored. Pretreatment is carried out according to the material properties. Recycled materials.

- Production process control: Calibrate 3D printing equipment regularly. Control printing parameters. Strict quality inspection is carried out.

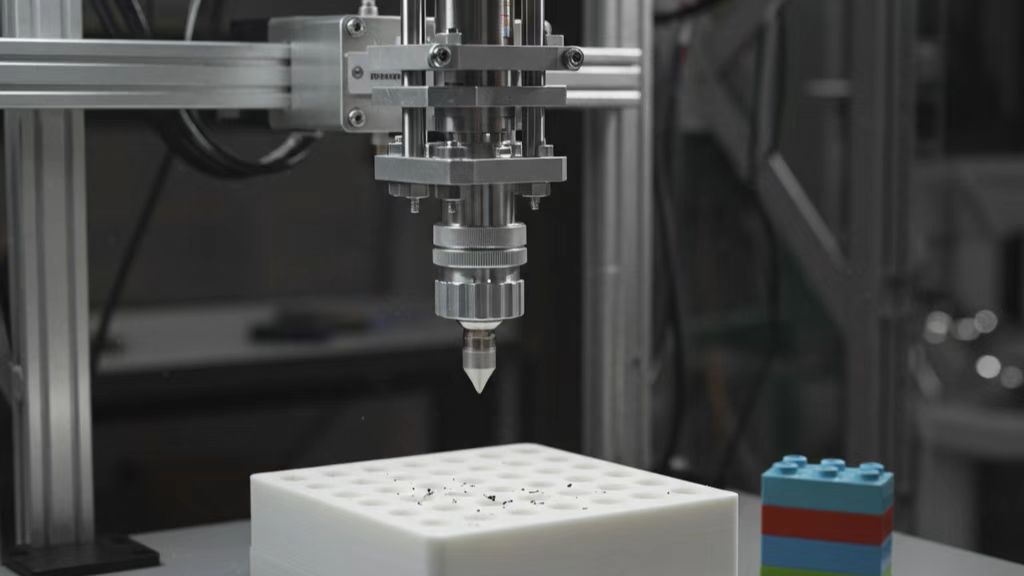

How to improve the automation and stability of 3D printing equipment?

The automation and stability of 3D printing equipment is the key to achieving efficient, high-quality, low-cost production. Printing equipment will develop in the direction of higher automation and higher stability, so as to expand its application in various fields.

- Equipment selection and transformation: Select high-automation equipment and carry out customized transformation to meet production needs.

- Control System Optimization: Optimize the control software and apply sensors to achieve precise control of equipment and fault warning.

- Equipment maintenance and maintenance: Regular equipment maintenance and preventive maintenance are carried out to ensure the long-term stable operation of the equipment.

- Process automation: Automate the printing process and post-processing processes to increase productivity.

How to optimize the 3D printing production process?

The 3D printing mass production process is a comprehensive process that starts with design, production planning, equipment, materials, quality control, and post-processing. Through improvement, production efficiency can be improved, production costs can be reduced, and product quality can be improved.

- Design Optimization: Simplify models, optimize nesting and support, and improve printing efficiency and material utilization.

- Production Planning & Scheduling: Make detailed plans, manage print queues, and use data to manage traceability issues.

- Equipment & Material Optimization: Select and maintain the right equipment, manage material inventory, and increase efficiency with automation.

- Quality Control: Real-time monitoring of the printing process, strict quality inspection, reduce scrap rate.

- Post-processing optimization: Utilize automated equipment for post-processing, standardize processes, and improve efficiency and consistency.

3D printing materials and features

|

The name of the material |

peculiarity |

Application scenarios |

| PLA (Polylactic Acid) | Easy to print and eco-friendly | Modeling, education |

| ABS (Acrylonitrile-Butadiene-Styrene) | Durable and heat-resistant | Functional parts, toys |

| PETG (polyethylene terephthalate) | Flexible, elastic | Food containers, outdoor products |

| TPU (Thermoplastic Polyurethane) | Flexible, elastic | Soles, phone cases |

| Nylon (PA) | High strength, wear resistance | Gears, bearings |

| ASA (Acrylonitrile-Styrene-Acrylate) | Good weather resistance, UV resistance | Outdoor parts |

| PC (Polycarbonate) | High strength, high temperature resistance | Engineered parts |

Quality and efficiency in mass production

In the mass production of 3D printing, the core goal is to achieve both quality and efficiency, which is not only related to the reduction of production costs and the enhancement of market competitiveness, but also affects the promotion and popularization of 3D printing technology in industrial applications.

- Quality is the lifeblood of mass production: Mass production must be based on a strict quality control system to ensure that the products meet the standards.

- Efficiency is the driving force behind mass production: Mass production maximizes economies of scale and profits by increasing efficiency.

- The balance between quality and efficiency is the art of mass production: mass production requires a balance between quality and efficiency to achieve harmony and unity.

conclusion

Mass production reduces the cost of a single piece through the large-scale effect, and improves manufacturing efficiency and resource utilization; Ensure product quality consistency and reduce human error; Promote the deep penetration of 3D printing technology into industrialization.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Mar-03-2025